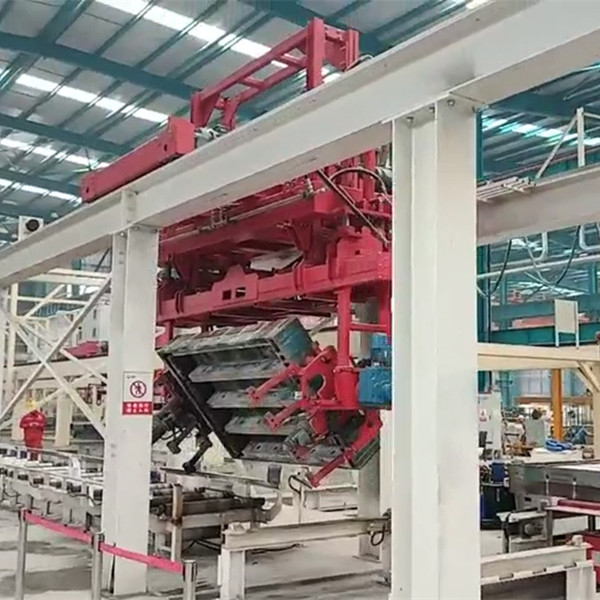

Prestressed Sleepers Production Line

★CompanyIntroduction

Hebei Xindadi electromechanical Manufacturing Co., Ltd. is a world leading technology enterprise of precast concrete processing equipment, and is committed to becoming a competitive enterprise of intelligent concrete processing equipment.The company now has four manufacturing bases in Zhengding, Xingtang, Gaoyi, and Yulin.We wholeheartedly provide customers with technical consultation and special design services for the factory production projects of precast concrete components, and system solutions for the whole life cycle of R & D, manufacturing, installation, commissioning and maintenance of complete sets of equipment, so as to meet the diverse needs of customers and create value for customers in all aspects.

★ Process Features

1.Using a combined steel mold (type 2×5), 10 sleepers are formed at one time, thereby reducing the loss of prestressed steel wires and improving production efficiency.

2.Concrete molding adopts secondary vibration process. The initial vibration is vibrated and compacted; the embossing vibration is to press out the pattern at the bottom of the sleeper and improve the concrete compactness.

3.The closed-loop process improves the continuity and rhythm of sleeper production and reduces non-productive transportation.

4.The curing kiln adopts pit curing kiln, which is sealed with water seal, which can effectively save energy; the curing uses steam curing.

5.Wide range of applicability, as long as the model is changed, other types of sleepers can be produced.

★System Features

1.Reasonable layout and novel process ;

2.Superior equipment performance, safety and reliability;

3.The production line is stable, reliable and safe;

4.Energy conservation and environmental protection;

5.Convenient maintenance