Recently, the first set of “Lightweight Wall Panel Intelligent Grooving Robot System”, developed by Hebei Xindadi, was put into use at a university in Jiangsu Province. This system is mainly used for on-site teaching in universities and vocational schools. It is used for modeling and operational demonstrations of grooving lightweight wall panels. The aim is to provide students with an understanding of the current wall partition production and processing technology in the construction industry, enhance their skills in flexible manufacturing and promote their integration into the field of intelligent construction.

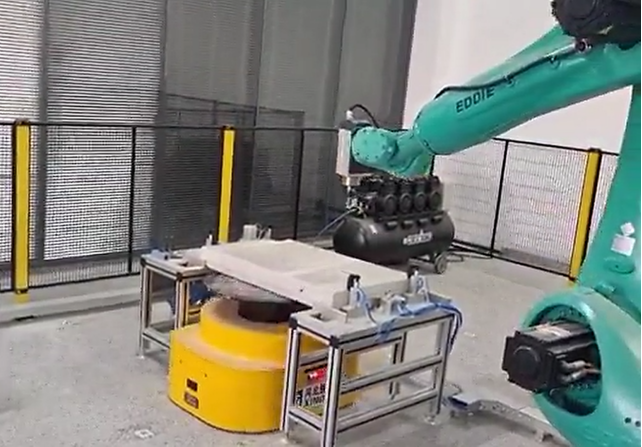

The Lightweight Wall Panel Intelligent Grooving Robot System consists of a robot system, robot end tools, AGV system, and other accessories.

By setting the robot’s motion trajectory and grooving parameters in the programming software, the robot can automatically perform grooving operations and ensure that each step is accurate.

In response to the problems of poor straightness, low efficiency, high labor intensity, and large amount of dust in the traditional grooving methods for lightweight wall panels, Hebei Xindadi conducted research on the “Lightweight Wall Panel Intelligent Grooving Robot System” to realize the application of robot automatic grooving on lightweight wall panels. The system can automatically complete the grooving operation of lightweight wall panels through modeling, and it has the advantages of high straightness, high efficiency, and easy operation.

The robot system uses a 6-axis robot with a maximum working radius of 2.7 meters.

The robot end tools include 3 alloy steel milling cutters with a 10mm shank, a maximum rotation speed of 12000r/min, a maximum revolving speed of 36000r/min, and a 4.5kW air-cooled spindle motor.

The AGV system can move in three directions: forward, backward, and rotation. The maximum walking speed is 30m/min, with a navigation accuracy of ±10mm, a stop accuracy of ±10mm, a lifting height of 50mm, and a driving method of dual-wheel differential drive.

The Lightweight Wall Panel Intelligent Grooving Robot System uses AGV for automatic conveying of lightweight wall panels, combined with robots and robot end tools to achieve automatic grooving of lightweight wall panels.

The successful implementation of this project can further enhance the teaching level of intelligent construction technology and provide professional training programs in the field of intelligent construction for universities. It contributes to the cultivation of high-quality technical and skilled personnel in the field of intelligent construction.

Post time: Sep-28-2022